Ngesivinini sokuthuthukiswa kwesayensi nobuchwepheshe, imikhiqizo eminingi yokubonisa manje isifakwe izikrini zokuthinta. Ukumelana futhicapacitive touch screenssezivele zikhona yonke indawo ezimpilweni zethu, ngakho-ke abakhiqizi betheminali kufanele benze kanjani ngokwezifiso isakhiwo kanye ne-LOGO lapho besekela ukuthinta? Yimiphi imininingwane okufanele inakwe lapho wenza ngendlela oyifisayo?

Lapha siqala kusukela ku-6 imininingwane ukwethula ukumelana kanyeisikrini sokuthinta i-capacitanceisikimu sokwenza ngokwezifiso ngokuningiliziwe:

1. Amapharamitha wokuthinta

Okokuqala, udinga ukuqinisekisa ukuthi umkhiqizo ufanelekile izikrini zokuthinta i-capacitive noma eziphikisanayo, futhi uqinisekise izinga lokushisa lokusebenza, izinga lokushisa lokugcina, isikhombimsebenzisi nezinye izidingo zepharamitha. Kungcono ukugxila ekuxoxeni nasekulungiseni ithebula lezidingo zepharamitha, okunganciphisa kakhulu isikhathi sokuqala sokuxhumana.

2. Usayizi we-AA kanye nosayizi wozimele wangaphandle

Ngemva kokuqinisekisa imingcele edingekayo, ngokulandelayo qinisekisa usayizi womkhiqizo. Usayizi ngokuyinhloko indawo ye-AA yesikrini esithintwayo kanye nosayizi wohlaka lwangaphandle. Laba osayizi ababili ngokuvamile baklanywe ngokusekelwe esakhiweni. Unjiniyela wesakhiwo udweba imidwebo ye-CAD ukuze iqinisekiswe, engathuthukisa ukusebenza kahle kokwenza ngokwezifiso.

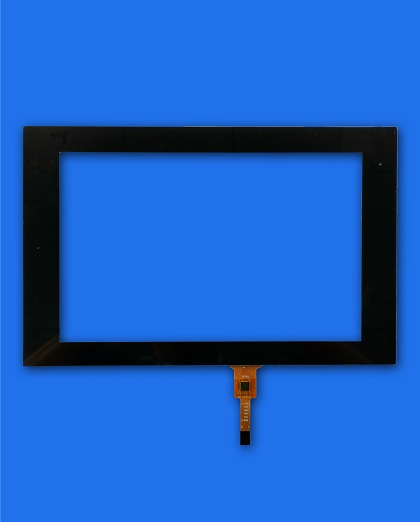

3. Ilogo yekhava yokuthinta

Ukuze uthole izikrini zokuthinta ezine-flat capacitive, ikhava yesikrini sokuthinta ingenziwa ngendlela oyifisayo. I-LOGO ephrintiwe ngosilika noma izithombe zingenziwa ngezifiso esikrinini sokuthinta. Uma amakhasimende edinga ukwenza ikhava ngendlela oyifisayo, angakwazi futhi ukuxhumana nomkhiqizi kusenesikhathi.

4. Isakhiwo sesikrini sokuthinta

Kunezinhlobo eziningi zezikrini zokuthinta, ezihlanganisa i-G+G, G+F+F, G+F, G+P, njll. Sicela uqinisekise isakhiwo sokuthinta. Isakhiwo ngasinye sinezici zaso. Ungathintana nesevisi yamakhasimende ukuze unikeze ezihlukahlukene Izinzuzo kanye nokubi zalesi sakhiwo.

5. Isikrini sokuthinta silingana

Ngokuvamile kunezinhlobo ezimbili zezindlela zokuthintwa kwe-lamination: i-optical bonding kanye ne-air bonding. I-Optical bonding isebenzisa umshini ozenzakalelayo ngokuphelele we-glue lamination yamanzi. Izinzuzo zayo ziwumphumela ongcono wokubonisa nokumelana nothuli, kuyilapho ukubopha komoya kunamandla. Ngayinye inezinzuzo zayo, futhi izimboni ezihlukene zisebenzisa izindlela ezihlukene ze-lamination.

6. Ukulungisa iphutha kwe-IC kwesikrini esithintwayo

Amasampula esikrini sokuthinta azolungiswa ngemuva kokuphuma embonini. Izinqubo zokuhlela zizohluka kuma-IC ahlukene. Amanye amabhodi amakhulu akasebenzisani kahle, ngakho ukulungisa iphutha nokushintsha uhlelo kuyadingeka ukuze kuzuzwe imisebenzi yokuthinta ebushelelezi.

Okokugcina, ake sifingqe indaba yesikhathi sokulethwa ngokwezifiso kwesikrini esithintwayo. Isikhathi sokulethwa sibaluleke kakhulu kumthengi. Ngokuvamile, uma wenza ngendlela oyifisayo kuphela ingilazi yekhava yokuthinta, isikhathi sokulethwa ngokuvamile siphakathi kweviki elingu-1 namaviki angu-2. Uma isikrini sokuthinta senziwe ngokwezifiso sisonke, isikhathi sokulethwa singaba yizinsuku ezingama-20, kuye ngesimo sezinto zokuqala. Uma izinto zingaphelele, idethi yokulethwa izoqinisekiswa ngokwehlukana.

I-DISEN ELECTRONICS CO., LTDigxile ekwenzeni izikrini ze-LCD ngokwezifiso, i-TP, futhi ingenza ngokwezifiso imikhiqizo ngokwezidingo zomsebenzisi. Uma unemibuzo, sicela ukhululeke ukuxhumana nesevisi yamakhasimende ku-inthanethi.

Isikhathi sokuthumela: Feb-29-2024